- View Mobile Number

info@innowerx.com

- Process Overview – Also called Additive Manufacturing, it is a process where part geometry is grown by depositing and fusing multiple layers one after the other. The part is manufactured as per the 3D CAD model and fed into its computing system. 3D printing can be classified into different types based on the type of material used for manufacturing.

3D Printing of Thermoplastic :

-

SLS (Selective Laser Sintering) – This 3D printing technology makes use of CO2 laser to fuse fine particles of thermoplastic powder to build part geometries. Parts made from this process do not require any post processing and hence can be directly taken up for end use. Parts made are highly accurate and durable but preferred for low volume production.

-

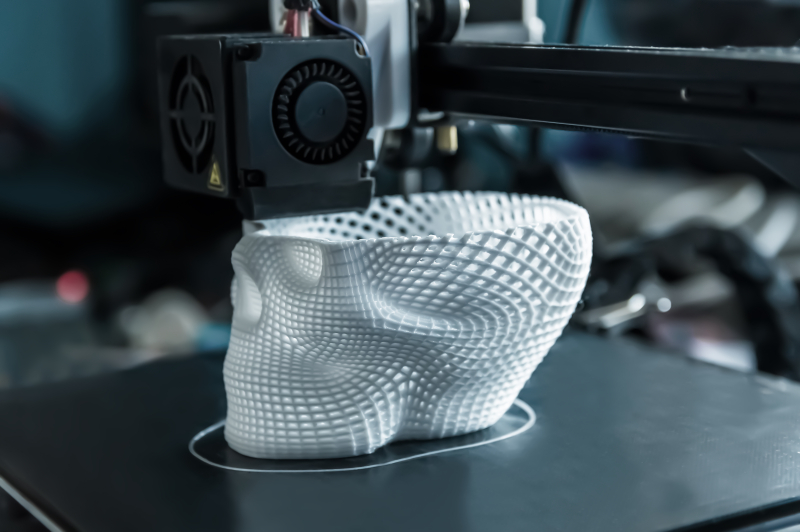

FDM (Fused Deposition Modelling) – In this method the feedstock is introduced into the system via an extruder which regulates the feed movement of the polymer to the heater where it melts. This molten polymer is extruded through a nozzle and deposited onto the print bed, also called as build platform. The extruder, heater and nozzle are all contained in a print head. This process is known for its speed, accuracy, and competitive cost.

3D Printing of Thermoset :

-

SLA (Stereolithography) – It is an additive manufacturing process that uses UV light on a liquid polymer resin to selectively solidify the part geometry layer by layer. After the printing is complete the parts are washed in a solvent solution to remove uncured resin and kept in a UV light oven for final curing. SLA printed parts have fine detailing and surface finish.

-

Polyjet – In this process a UV curable resin is jetted onto a build platform in ultra-thin layers along with a gel like support material. The build platform moves downwards as each layer is cured by UV light and the process is repeated. The support material is removed by water jetting and the parts can be used immediately after curing. It can be used to make parts of different materials, colors, and transparencies in a single build with high accuracy, speed and fine details.

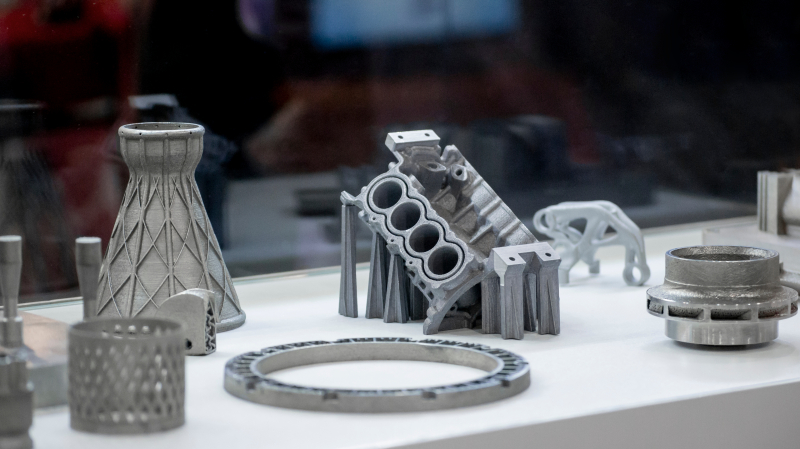

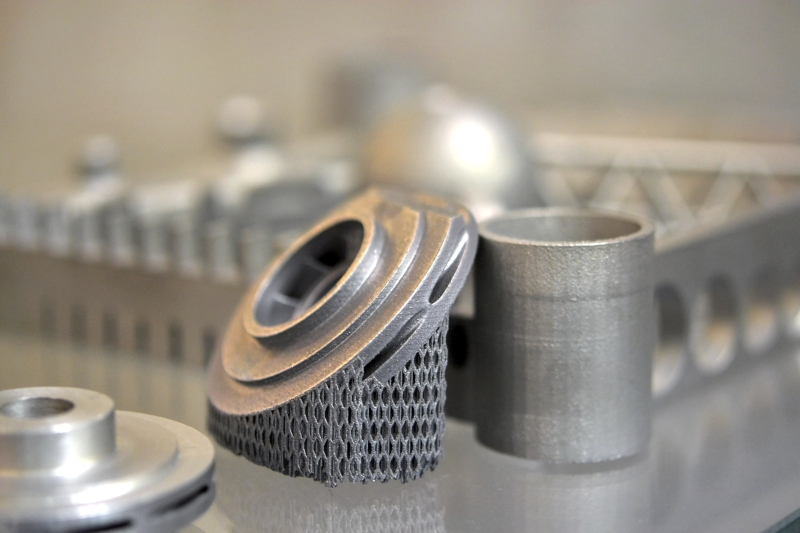

3D printing of Metal :

-

DMLS (Direct Metal Laser Sintering) – This process is most ideal for 3D printing of metals as it uses heat of a laser to fuse metal particles together in subsequent layers. The laser is guided along the scanning bed as per the 3D CAD model. Once the printing is complete the excess powder is removed, and the part is heat treated to remove residual stresses. It can be used to make metal parts with complex geometry and intricate shapes.

-

Metal Binder Jetting – In this process the metal powder is first fused together with a binding agent. Once the part is bound the resultant shape is called a green part and is left to cure which is then put in a furnace for sintering. These parts are prone to shrinkage and are slightly porous.

-

Capabilities

-

Rapid prototyping of parts in less than 5 days based on project scope

-

Manufacturing of parts for the Healthcare sector such as dental implants, anatomical models, surgical guides, orthotics etc.

-

Manufacturing of small and intricate jewelry items

-

Wide range of selection of materials as stated above

-

Flexibility in selection of process for manufacturing of parts based on material used

-

Manufacturing of prototype as well as production parts

-

-

Application and Benefits

-

3D printing has rapidly advanced in recent years due to due to its ostentatious offerings and has found extensive applications in Aerospace, Defence, Jewelry, Consumer products, Prototyping etc.

-

Complexity – It can easily manufacture complex and intricate shapes and profile

-

Flexibility – Different process can be adopted for manufacturing of a part with same material based on its characteristics

-

Precision – Parts with narrow dimensional tolerance and high accuracy can be manufactured

-

Repeatability – Parts can be made with highest rate of repeatability compared to any alternate manufacturing process

-

Material selection – Can be used to make parts from almost any material such as ferrous and non-ferrous alloys, plastics etc.

-

Versatility – Almost any part can be manufactured within the limits of the machine size

-

Rapid Prototyping – Prototypes can be made in less than 5 days saving huge time and cost

-

-