- View Mobile Number

info@innowerx.com

-

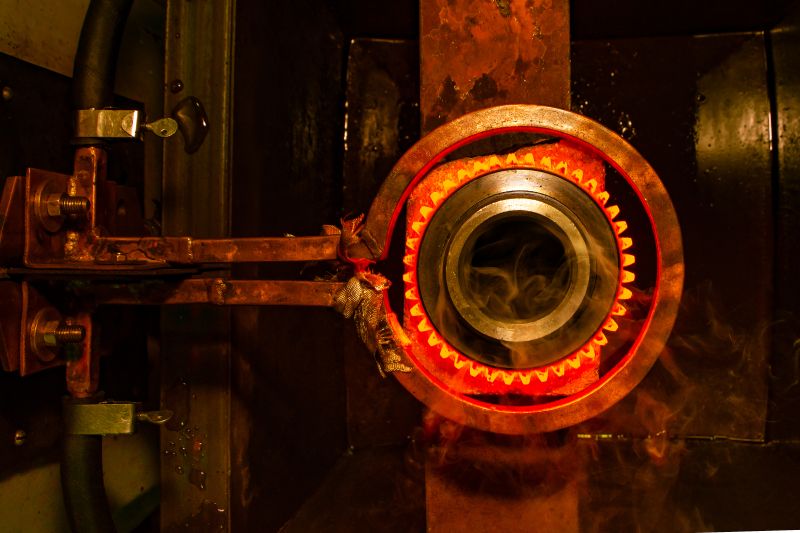

Process Overview – Process of heating metal without letting it reach its molten state and then cooling it in a controlled manner to achieve desired mechanical properties. The Heat Treatment consists of : a) heating cycle in which the part is heated at a consistent rate till a certain temperature b) soaking cycle in which the part is held at a particular temperature c) cooling cycle in which the part is cooled using different cooling media to achieve the desired properties. The cooling cycle is the most crucial stage of HT cycle as it determines the final grain structure thereby influencing the mechanical properties of the metal. Heat Treatment is broadly classified as Bulk and Surface Heat Treatment.

Few common Bulk Heat Treatment process performed by us are :

-

Annealing and Normalizing – These processes are used to refine and homogenize the grain structure to remove residual stresses and improve machinability. The only difference between Annealing and Normalizing is the former is furnace cooled and the other is air cooled.

-

Hardening and Tempering – The purpose of hardening is to increase the hardness of steel by producing a fully martensitic structure through controlled cooling rate whereas tempering is to relieve the residual stresses induced during hardening and improve toughness and ductility of steel. Hardening is mainly characterized by composition of alloy, type of quenching medium and size and shape of part.

Few common Surface Heat Treatment process performed by us are :

-

Carburizing - It is a thermochemical process in which carbon is diffused into the surface of low carbon steels to increase the carbon content to sufficient levels so that the surface will respond to heat treatment and produce a hard, wear-resistant layer.

-

Nitriding – It is a thermochemical process in which nitrogen is diffused in alloy steel to form a hard surface. It is further classified as Gas, Liquid and Plasma nitriding based on the media being used.

-

Carbonitriding – It involves diffusion of both carbon and nitrogen into the surface of steel substrate.

-

Capabilities

-

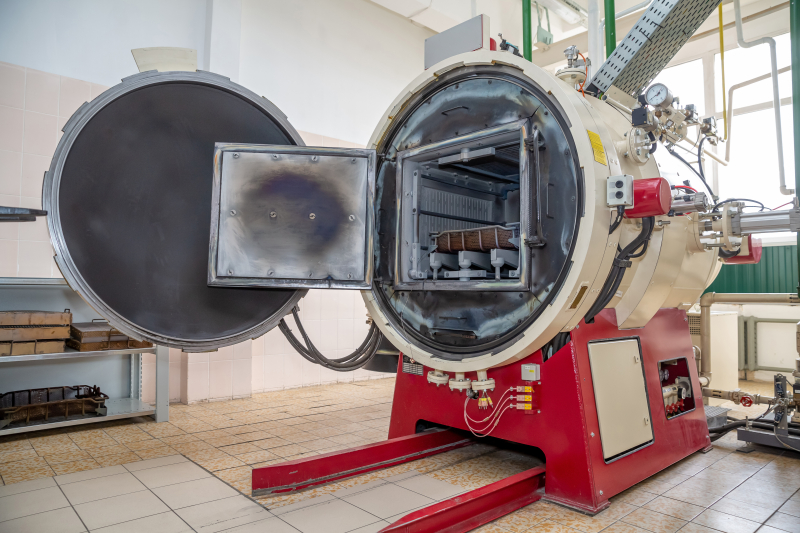

All heat treatment processes under one roof

-

Completely automated and PID controlled heat treatment furnaces

-

Paperless recording of heat treatment cycle with complete traceability

-

Multiple furnaces to cater mass production

-

Flexibility to load batch and production parts

-

Vertical furnace up to 2 meter Dia and 8 meter height for loading of long shafts and rollers

-

Heat treatment of raw as well as machined parts

-

In-house and third-party testing of heat-treated material for verification of required mechanical properties

-

Heat Treatment facility certified to ISO 9001 and IATF 16949 Quality Management System

-

Periodic calibration, maintenance, leak testing and temperature uniformity survey to ensure process reliability and consistency

-

-

Application and Benefits

-

Heat Treated steels are used in almost every industry sector such as Aerospace, Automotive, Oil & Gas, Power Generation, Steel, Pumps and Valves, Hydraulic, Air and Gas Compressor, Construction etc.

-

Heat Treatment is the most effective and efficient method of achieving the desired mechanical properties by altering the grain structure of a conventional steel. Few advantages of Heat Treatment are as follows :

-

Improving wear and corrosion resistance

-

Improve fatigue strength

-

Improve toughness

-

Increase machinability by improving malleability and ductility

-

Improve cold press property

-

Improve other properties such as magnetic, thermal, and electrical properties

-

-